Condition monitoring

PVS SmartAir

Compressed air condition monitoring

Flow, volume, pressure and humidity – PVS SmartAir

Reduce your compressed air consumption costs by up to 30% and take control of your compressed air quality using PVS SmartAir and its digital sensors.

Why should the quantity and quality of compressed air be monitored?

Compressed air is used in industry to generate movement of production equipment, change the trajectory and, among other things, maintain grip properties. Typical uses include various blowing operations, conveyors, the use of presses, grippers, tools and spray booths, as well as numerous other applications. Compressed air can therefore be considered one of the most important industrial commodities, right after electricity.

At the same time, compressed air is one of the most expensive forms of energy. Did you know that up to 96% of the electrical power consumed by a compressor is converted into thermal energy? The compressor's heat recovery potential is also enormous, as up to 70% of it can be utilized, for example, to heat domestic water to temperatures of up to over 70 degrees Celsius.

According to some calculations, the cost of compressed air is up to eight times higher than the price of electricity. Compressed air has a correspondingly poor CO2 balance – especially since compressed air leaks and inefficiency can further reduce efficiency. Partly because of this, many companies compensate for the CO2 emissions of the electricity they purchase by purchasing “green” or “emission-free” electricity.

Do you want more information?

Contact Us

Sami Uusi-Erkkilä

SmartAir And Energy Oy's business idea is very simple. We provide energy and cost savings to the compressed air industry and help in the green transition for compressed air.

SMARTAIR

ISO50001 energy management system + PVS SmartAir

SMARTAIR

Why is PVS SmartAir unique?

Compressed air is produced by compressed air compressors, after which it is post-processed and transferred through the network for use. PVS SmartAir sensing is installed in the pipeline before the compressed air is transferred to the consumption points for use. So we do not monitor how an individual compressor works, but we produce critical data on the most important values of compressed air such as flow, pressure and dew point. We produce data as follows:

✓ flow, m3/min

✓ quantity, m3

✓ pressure, bar

✓ temperature, °C

✓ device room temperature, °C

✓ dew point, °C

SMARTAIR

The importance of flow, pressure and dew point

Compressed air allows a company's operations and processes to operate smoothly and energy-efficiently.

When the pressure and flow of compressed air meet the requirements of the process, production also works perfectly. The dew point is important when it comes to the quality of compressed air. The dew point value refers to the operation of a separately defined and purchased after-treatment equipment and the quality of the compressed air it produces in terms of moisture content.

Flow

If the flow rate is less than the process requirement, the compressed air balance is negative. As a result, the pressure in the network is directed downwards, i.e. the pressure in the pipeline decreases. In terms of flow, compressed air compressors must produce at least the flow required by the process. For uninterrupted production, arranging spare capacity is also critical for both maintenance and failure situations.

Pressure

Did you know:

1 bar = 100,000 pascals (Pa)

1 bar = 100 kilopascals (kPa)

1 bar = 0.1 megapascals (MPa)

1 bar = 14.5038 pounds cm2 (PSI)

Dew point

The dew point is the temperature to which air must be cooled in order for the vapor in it to condense into dew or frost. The term pressure dew point is an established term for describing the moisture content of compressed air. In this case, the dew point of compressed air at the prevailing pressure indicates the absolute amount of humidity, and it cannot increase any further. The amount of humidity is expressed on the Celsius scale, for example -40 °C, where the dew point in vapor form can condense into droplets due to a decrease in external temperature.

✓ Conventionally, the dew point is defined according to the ISO8573-1 standard

✓ Level 4 corresponds to the maximum moisture content at a temperature of +3 °C.

✓ Level 2 is very typical, but clearly more critical than level 4.

Level 2 means the amount of moisture equivalent to -40 °C, which is only 21% of the moisture content of level 4.

Read more about the compressed air quality standard ISO 8573-1

https://www.beko-technologies.com/en-en/know-how/compressed-air/compressed-air-quality/

SMARTAIR

BENEFITS OF COMPRESSED AIR CONDITION MONITORING – PVS SmartAir

Reducing compressed air costs, ensuring production reliability and monitoring quality

✓ Water meters are used in buildings to measure the amount of water consumed. In the case of compressed air, this means flow measurement, which determines the current consumption of compressed air and the amount of compressed air used.

✓ Without data, there is no knowledge – only best guesses. Compressed air costs can be effectively controlled by reducing both usage and waste and optimizing system performance.

✓ In addition to continuous compressed air condition monitoring, our Ovaport cloud solution has possible to detect compressed air leaks at a very early stage.

✓ Our alarm function warns in advance if the system network pressure drops to the alarm limit. The alarm limit is set to a level that indicates a system failure but production failures have not yet been activated. In accordance with a similar principle, alarm limits critical to the factory's operation are also set for the compressed air flow and dew point.

✓ Our operating philosophy is to react to critical data generated by the system before production is compromised. Compromise in production always has a negative economic and production impact. At worst, it can lead to the deterioration of a quality-critical end product and impacts on human health and well-being.

✓ Inefficiency in your compressed air system is easy to detect with the data generated by PVS SmartAir. Contact our sales team and we will tell you how we can help you.

Read more about Walk's success story.

Starting at 99 euros per month

PVS SmartAir system as a service

You don't have to own everything. If necessary, you can purchase PVS SmartAir as a service, where we provide the necessary sensors and cloud service.

✓SmartAir is responsible for the design of the installations, the customer for the installations and their costs.

✓the equipment does not become the customer's property but is returned to the supplier when the contract expires

✓The monthly price does not include the costs of implementation, expert services, installation, supplies and freight.

✓starting price includes: 1 x flow sensor inline ½”-2”, cloud service and PVS SmartAir portfolio with necessary components. Data transfer and license fees as well as remote commissioning. Contract duration is 5 years.

SMARTAIR

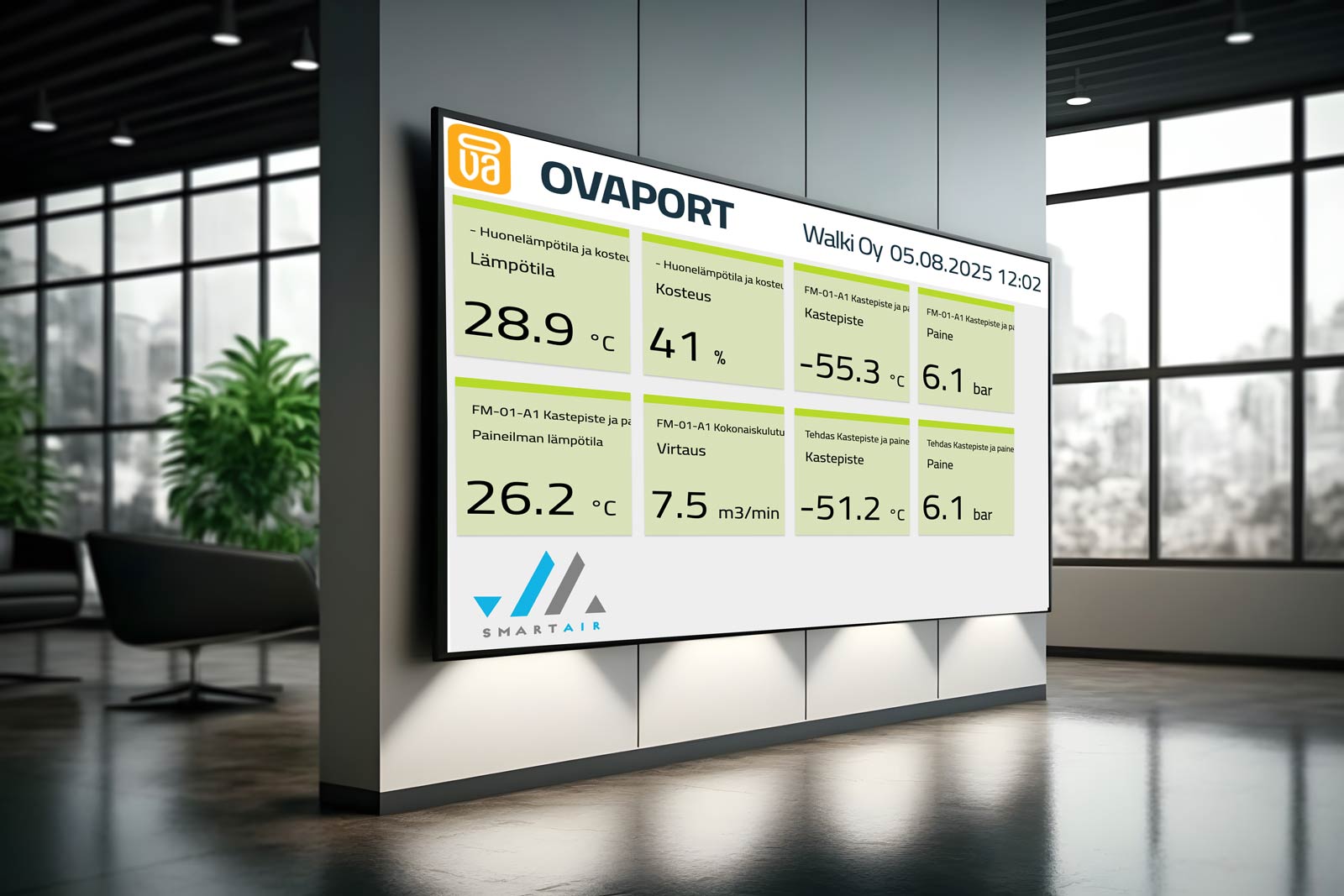

PVS SmartAir – Monitor wherever you want

Information displays for public spaces

Reducing our customers' compressed air energy consumption and energy efficiency are among the most important goals of our operations at SmartAir.

We specifically use our Ovaport cloud solution for compressed air condition monitoring. If you wish, you can use the info display feature. Simply copy the link from our service and play it on the desired screen.

SMARTAIR

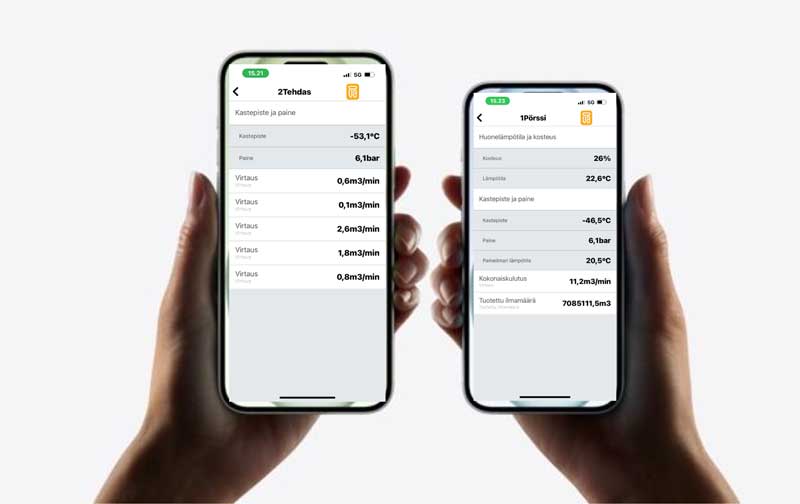

With a mobile app – when the need arises

The mobile app goes wherever you go.

SMARTAIR

Terminal devices – at your own workstation

At your workstation, you can open the Ovaport view in your own browser tab. One glance and you will get all the important information. If the set alarm limit of the monitored values is reached, the green “all is well” color will change to red. When the color is red, you are being notified that something may be happening and your attention is needed.

The system also sends automatic messages either to email or phone.

SIMPLE IS BEAUTIFUL

PVS SmartAir is comprehensive compressed air condition monitoring

PVS SmartAir is a digital compressed air condition monitor consisting of three components that are perfectly integrated:

✓ compressed air flow and dew point sensors

✓ Solid-Sky wireless transmitter, Cell-Sky base station and installation kit

✓ From the Ovaport system, which is accessed using a web browser

The seamless interaction of these components ensures user-friendly, efficient and comprehensive condition monitoring of the compressed air system, which can be seamlessly integrated into the company's ISO50001 energy management system.

SMARTAIR

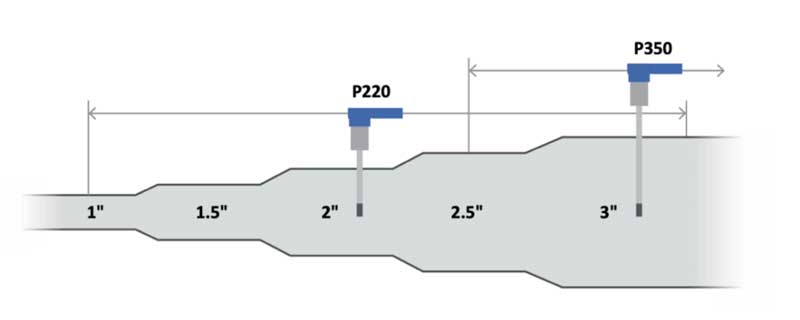

We help you choose the right sensors

The choice of sensors is determined by the installation environment and purpose. Compressed air condition monitoring can consist of a single flow measurement after the compressed air station and extend to individual monitoring of individual consumption points or production lines. If there are several compressed air stations in the factory, it is justified to equip each station with its own measurement.

The following points are taken into account when selecting a sensor;

✓ the medium to be measured, whether it is compressed air, nitrogen or some other industrial gas

✓ flow range and pressure

✓ installation location and pipe size

✓ Installation method, Inline or Rod

✓ number of sensors

✓ data collection method, PVS SmartAir or building automation

The SmartAir design team is here to help you with the right sensor selection and installation. Please remember that compressed air flow sensors are intended for dry and clean compressed air. However, the VPFlowScope DP – Differential pressure flow meter is available separately for wet compressed air.

Flow sensor selection table

Type Pipe size Flow range

Inline ½” 0.0-1.3 m3/min

Inline 1” 0.0-4.2 m3/min

Inline 2” 0.1-16.7 m3/min

P220 1” 0.0-5.0 m3/min

P220 2” 0.1-19.5 m3/min

P220 3” 0.2-42.3 m3/min

P220 4” 0.3-73.9 m3/min

P350 2” 0.1-19.5 m3/min

As well as all intermediate sizes DN50-DN400

P350 16” 3.4-1026 m3/min

SMARTAIR

Flow sensors

The rod-type P220 and P350 are excellently suited for flow measurements in the process industry, thanks to both the installation method and the wide measurement range.

The measuring range of the sensors is determined by the pipe size in the target. We are here to help you choose the right sensor type.

Inline Flow Sensors are available in ½”, 1” and 2” pipe diameters. The sensor achieves best performance at flow rates between 10 and 100% of the standard % measuring range. Sometimes less is more. For example, downsizing a DN20 pipe to DN15 can result in higher accuracy and a smaller measuring range.

Efficiency, environmental friendliness, costs - what else?

✓Efficient production of compressed air

Continuous monitoring of compressed air conditions detects deviations and cost factors. This enables you to avoid unnecessary energy costs and increase production efficiency. The information obtained serves as the basis for data-driven decisions that increase efficiency sustainably.

✓Produce in an environmentally friendly way

Monitoring your compressed air system leads to savings in energy costs and carbon dioxide emissions, protecting the environment and promoting sustainable production.

✓Reduce production costs

Identifying excessive compressed air consumption and inefficiencies in compressed air systems enables production costs to be reduced and leads to increased overall profitability. Potential savings can be measured and displayed through data-driven profitability calculations.

Are you aware that a 1 bar pressure increase increases the energy requirement for compressed air production by 7%?

✓Reduce maintenance costs

Need-based maintenance saves companies time and effort, and thus money. The data generated by the Ovaport service and the relevant warning messages generated by the system ensure transparency and provide the basis for avoiding unplanned maintenance work.

Sales

SmartAir & Energy Ltd.

By choosing PVS SmartAir, you are investing in a system that offers:

✓ Complete transparency compressed air system performance

✓ Plug & Play installation, and data availability on the same day

✓ Includes measurement data and analytics, which supports energy economy optimization and billing fairness

Contact us

and let's find out together how PVS SmartAir can save your factory energy, costs and carbon dioxide emissions - easily and measurably.

CUSTOMER FEEDBACK

What our customers say about us

Sinituote Oy

SmartAir provided us with a leak analysis of the Kokemäki factory's compressed air system and

analysis of energy use, both in terms of compressed air production and leaks.

We think the service they provide is very informative and we have not had it before

the idea that almost all of the electricity used by 10% goes into compressed air.

The project's payback period is approximately 1 year once the leaks are repaired, which will generate energy savings for us in the future.

We can definitely recommend SmartAir

Alexander Talzi

Project Manager

Sinituote Oy – Akaa factory

The leak detection of the compressed air system and the energy recovery discussion were a development step for us.

in the right direction. We didn't realize before that a 1/2-day assignment could be so effective.

We received the necessary information, made the required repairs, and the project was completed.

Jussi Mattila

Foreman

A VERSATILE EXPERIENCE

Set of values

We work in collaboration with our customers, providing them with added value in terms of both energy and cost adjustments.

With all our solutions, we aim to be ecological, reduce emissions or minimize their generation, and provide energy-saving solutions.

With the help of our innovative and professional design team, our solutions will last far into the future.

We have diverse experience in various industries such as;

✓ Foodstuff

✓ Paper and process industry

✓ Power plants and energy production

✓ Chemical industry

✓ Technology and engineering workshop

✓ Metal processing

✓ Processing of recycled materials

✓ Industrial energy services

✓ Primary production and agriculture

✓ Material transfers

✓ Defense equipment industry

✓ EV battery industry

✓ Research and product development

✓ Electronics

✓ Textile

✓ Electrical cable manufacturing

✓ Compressed air training services

We serve our customers from Tampere, the compressor capital of Finland, all the way from Hanko to Ivalo.

Year

Experience with compressed air.

Over 1000

Supplied compressed air system.

kW Asti

Compressor and system sizing.